| Name: | Resonant tuning fork density meter |

|---|---|

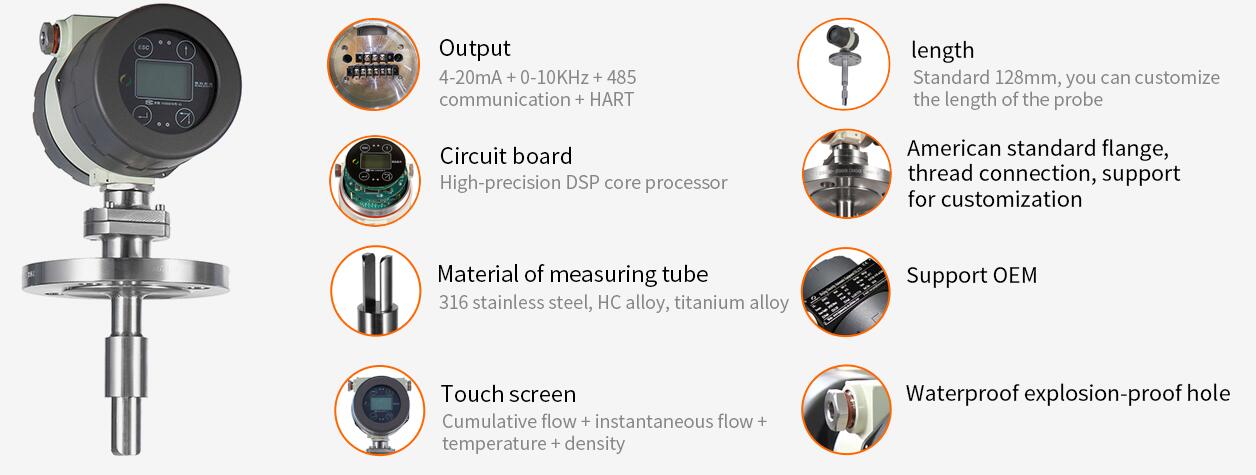

| Probe material: | SS316L, Hastelloy, SS316L lined with PTFE, Hastelloy lined with PTFE |

| Process Connection: | DN50 HG/T 20592- -2009 RF or Chuck |

| Probe length: | Standard 128mm(customized) |

| Power supply: | 24VDC or 220VAC |

| Working pressure: | 1.6MPa 4.0MPa |

| Output: | 4-20mA, RS485 Modbus RTU,HART |

Choose your own customized parameters

| 1 | Code | Probe material | |

| A | 316L stainless steel | ||

| B | Hastelloy | ||

| C | 316L stainless steel lined PTFE | ||

| D | Hastelloy lined PTFE | ||

| 2 | Code | Transmitter output | |

| E | 4-20mA 0-1000Hz RS485 Modbus RTU | ||

| 3 | Code | power supply | |

| A | 24VDC | ||

| B | 220VAC | ||

| 4 | Code | Transmitter housing | |

| F | Aluminum alloy | ||

| 5 | Code | Pressure Level | |

| 16 | 1.6MPa | ||

| 40 | 4MPa | ||

| XXX | Special: Use this letter to apply for special | ||

| 6 | Code | Process connection | |

| A | DN50 HG/T 20592- -2009 RF | ||

| B | Chuck | ||

| XXX | Special custom | ||

| 7 | Code | Pole length | |

| 128 | Standard length 128mm | ||

| XXX | Special: Mark the required length | ||

| 8 | Code | Extension rod material | |

| A | No extension | ||

| B | 316L stainless steel | ||

| C | Hastelloy | ||

| D | 316L lined with PTFE | ||

| E | Hastelloy lined PTFE | ||

| 9 | Code | Flange material | |

| A | 316L stainless steel | ||

| B | Hastelloy | ||

| C | 316L lined with PTFE | ||

| D | Hastelloy lined PTFE | ||

| 10 | Code | Installation method | |

| A(XX) | Horizontal pipe (XX: user pipe diameter) | ||

| B(XX) | Vertical pipe (XX: user diameter) | ||

| C | Tank installation | ||

| D | Special: Use this letter to apply for special | ||

| 11 | Code | Factory setting | |

| G | Factory setting options | ||

· Measure density ,concentration ,gravity, temperature of liquid

· The accuracy will not be affected by temperature, pressure,density, viscosity, etc.

· Accuracy: ±0.002g/cc; ±0.001g/cc optional

· Applications:pipeline interface detection ,mineral slurry solids monitoring,and corrosive acid concentration control;Where fast-response density and concentration monitoring is required.

· Increase installation flexibility with continuous, real-time measurement in pipelines, by pass loops and tanks

· Choose from a wide range of corrosion-resistant materials for measuring density and concentration of critical chemicals Support protocols for connection to DCS, PLC and flow computers

· Expand usage with a hazardous area-approved, head-mounted transmitter that supports local configuration and display

Resonant tuning fork density meter can measure the density, concentration, gravity, temperature, and accuracy of liquids without being affected by temperature, pressure, density, and viscosity. Applications: Pipeline interface inspection, slurry solids monitoring and corrosive acid concentration control; density and concentration monitoring that require rapid response. Continuously measure pipelines in real-time through pipelines and storage tanks to increase installation flexibility and choose from a variety of corrosion-resistant materials to measure the density and concentration of key chemicals. Supports protocols connected to DCS, PLC and flow computers. Pass Hazardous Area Approved Head-Mounted Transmitters extend the range of use, the transmitter supports local configuration and display.

General

- Liquids with transient gas entrainment

- Cryogenic or high temperatures (-200…+400°C /-328…+752°F)

- Super critical gases

- Custody transfer (CT)

Chemical and other process industries

- Concentration and density measurement

- Bulk loading

- Batching and blending to reactors

- Hydrocarbon cracking

Oil and gas industry

- Metering skids, bulk loading, pipeline transfer

- "Bypass" density measurement

- Liquefied Natural Gas (LNG)

- Bulk loading

- In-line density measurement

- Multiphase measurement in upstream applications

Food and beverage industry

- Batching, dosing, filling

- Mass flow measurement of ice cream and milk (e.g. at the raw milk reception)

- Measurement of flow, density, specific gravity in brewing processes - Dosing of hop extract

- Measurement of Brix, density and flow in fruit juices

- Dosing of natural oils, grease, vegetables (e.g. spinach) etc.

- CO2 injection in soft drink production

Pharmaceutical industry

- Batching, dosing, filling

- Solvent extraction

Marine industry

- Bunkering and fuel consumption measurement

Pulp and paper industry

- Additives, bleaches and colourants

- Crystallising, solidifying and cryogenic products